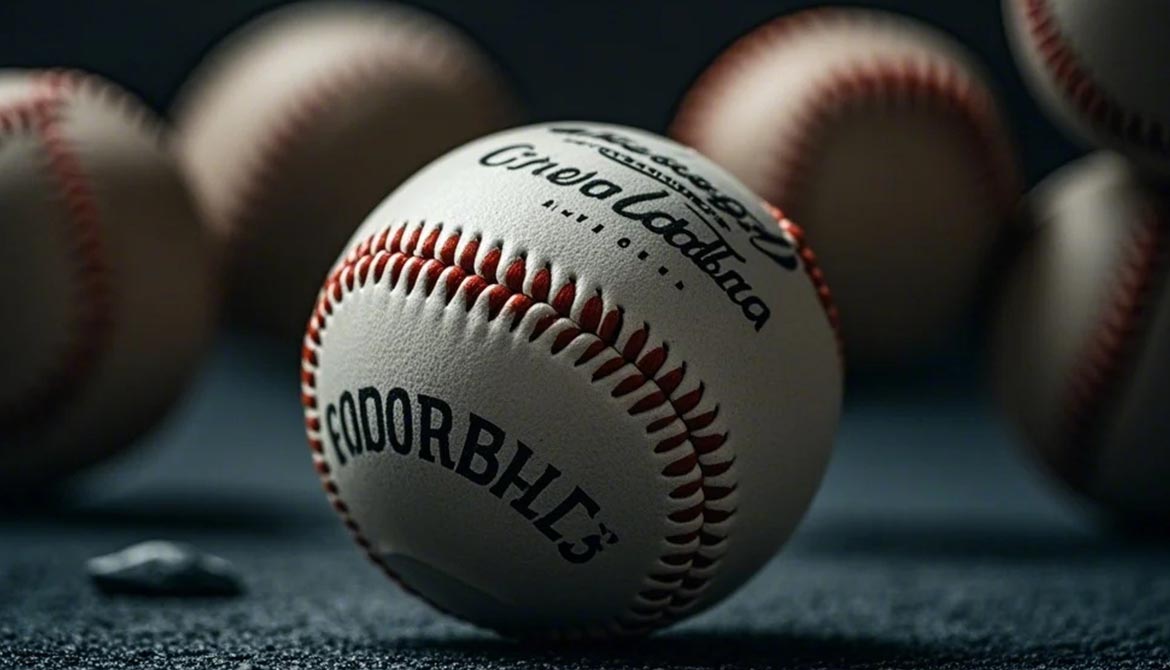

Baseball

Type

Training Balls, Indoor/Soft Baseballs, Recreational

Material

Premium Cowhide Or Horsehide Leather

Printing

Screen Printing, Digital Direct Printing, Etc.

Regulatory

5–5.25 Oz, 9–9.25 Inches, 108 Double Stitches

1. Design & Material Selection

Core Components:

Center: A cushioned cork or rubber core (often wrapped in rubberized adhesive for resilience).

Yarn: Wool (for elasticity) and polyester/cotton blends (for durability) layered around the core.

Cover: Premium cowhide or horsehide leather (MLB uses cowhide) cut into two figure-8-shaped panels.

Regulatory Compliance: MLB standards specify weight (5–5.25 oz), circumference (9–9.25 inches), and stitch count (108 double stitches).

2. Core Creation

Cork/Rubber Core:

Cork is compressed into a sphere, coated with rubber adhesive, and cured.

For rubber cores, synthetic rubber is molded under heat and pressure.

Rubberized Coating: The core is dipped in a rubberized solution to enhance bounce and durability.

3. Yarn Winding

Inner Windings:

First Layer: Wool yarn is tightly wound around the core by automated winding machines to build elasticity.

Second Layer: Polyester or cotton-blend yarn adds structure and durability.

Tension Control: Precise tension ensures uniformity and consistent performance.

4. Cover Assembly

Leather Cutting:

Cowhide is split, tanned, and dyed before being die-cut into two figure-8 panels.

Cover Stitching:

Hand-Stitching (Premium/MLB): Skilled workers sew the panels with red cotton thread using a saddle stitch (108 stitches per ball).

Machine Stitching (Recreational): Automated machines replicate the process for cost efficiency.

Seam Rolling: Stitched seams are rolled to flatten and ensure aerodynamic consistency.

5. Finishing

Surface Treatment: Balls are polished to smooth the leather and remove excess thread.

Branding: Logos, league certifications, and manufacturer details are stamped onto the cover.

Compression Testing: Balls are tested for rebound height (e.g., 54–58 inches when dropped from 10 feet).

6. Quality Control

Weight & Size: Each ball is weighed and measured to meet league specifications.

Compression Test: Ensures consistent hardness and bounce.

Seam Inspection: Stitches are checked for tightness and alignment.

Durability: Balls are fired against bats or walls to test cover integrity.

7. Packaging

Retail: Wrapped in plastic, boxed in dozens, and labeled with league certifications.

MLB-Grade: Packaged in climate-controlled boxes to preserve leather quality.